Designer, Brad Sheehan on 2020

With the launch of the 2020 Collection, sit down with Velocio CEO and co-founder Brad Sheehan and learn what influences the design and creation of the collection and what sets it apart from other apparel.

The Spring/Summer 2020 Collection has launched this week. There are more recycled and natural fiber fabrics used, more options for color and design and a continued focus on evolving patterns and styles. How did you come to these changes and what makes this collection stand out from past Velocio pieces?

The development of each season starts for me with a reflection on the prior year – what worked, what didn’t, where we can improve. I look at our customer reviews (I read every review submitted) and our sales data. I lean on our internal team and our ambassadors for detailed feedback as well as input on what’s missing. All of these points inform what’s next.

Each style is pulled apart to see where it can address the feedback and testing to make adjustments: lighter, more supportive, etc, etc. to incorporate updates to pattern, fit and materials develop the starting point for each new season. For example, with our Signature and SE jerseys we looked to improve stability and support while maintaining the incredible softness and light weight.

For 2020 we also sought to push forward our commitment to more sustainable fabrics and resources. We’d been using recycled fabrics in a select number of products and have since worked with our suppliers to see where we can push that. Every jersey in our collection is either made primarily from recycled polyester (ocean trash from EU - turned into new yarn in EU) or natural fibers. Each of our suppliers meets BlueSign and/or Oeko-tex certifications as well.

Design and color both play a big role in every collection, where we look towards what’s new for the season ahead as well as work to carry a core palette and design aesthetic from season to season. This can be one of the most challenging aspects of producing a collection like this, since most of these decisions are made more than a year in advance of the collection launch.

It’s important to me that we’re creating collections that are cohesive and connected visually so that a jersey you purchased two years ago will coordinate with a new bib short or vest from this season. That “timelessness” designed into what we produce is purposeful - understanding that Velocio is an investment and we want our designs to have the same longevity as the fabrics they’re created from.

2020 is by far our biggest yet, offering more colors, prints and styles than any collection prior. Each year we also refine every style and build awareness and appreciation from our customers, which gives us more opportunity to push what’s possible both from a materials and design perspective. S/S ‘20 is the result of that.

What are pieces of this collection that might go unnoticed, tweaks to design or changes in longtime pieces?

I’m really excited for the new Signature jersey. It’s one of those that often gets overlooked due to its simple aesthetic, but technically it’s an incredible jersey. The fit and feel are super and the re-design for 2020 is probably going to make it my go-to this season.

The Ultralight bib short is another that could go under the radar. It’s really difficult to describe how unique these are. We redesigned them for 2020 with a woven fabric (most bib shorts are made with knit fabrics), which gives an incredible level of compression and muscle support in a weight that’s just not possible with knits. They’re so thin and light, but not see-through. Awesome for mid-summer.

And on the TRAIL side, I’d have to say the Delta Long sleeve. This has been a favorite of mine and I’ve heard many times from people that have tried it how much they like it - much more than they thought possible from what looks like a pretty simple jersey.

The collection is larger than ever and featuring pieces designed for more types of riding than ever. What’s the process you go through to make something like the RECON Micromodal or the Radiator Mesh?

Anything I design starts with the rider: how it needs to perform, what “problem” it needs to address, how it should feel, fit or function. From there, I look at what fabrics and construction are going to get us as close to those rider requirements as possible.

A few examples:

RECON Micromodal was developed around the idea of creating a t-shirt for gravel/exploration or bikepacking. “I want to ride in a super soft t-shirt, but I need pockets”. And there are benefits to cutting the piece to be more tailored like a jersey, where breathability and wicking performance is improved. These were the inspiration for a zipperless jersey that’s made of an incredibly soft modal microfiber yarn. There’s even a carbon thread in it to help with anti-microbial and odor reduction (think multi-day bike packing tours).

Or Radiator Mesh: I need a jersey that works when it’s a billion degrees outside and doesn’t feel like it’s suffocating me. There really was nothing on the market that had true hot weather function. Sure there are mesh jerseys, but all they’re doing is increasing airflow - they’re not providing any benefit in terms of evaporation/cooling. With Polartec Delta we were able to create a jersey that acts much like an ice vest, providing actual evaporative cooling as you ride.

I’ve found that if you’re willing to strip away what’s considered the norm, there’s a lot of room for innovation and better product. It’s what motivates me and why we’ve been able to produce some really unique products over the years. For sure as the collection grows, this makes my job more challenging, but the fundamentals remain, and that’s rider-focused design.

Despite a commitment to sustainability, you’ve pointed out some of the challenges with reducing carbon costs or affecting supply chain. If you could wave a wand and make changes, what would you do and why?

Oof: That’s a big question. I spend a lot of time thinking about this, researching and discussing with suppliers and manufacturing. Reality is, “Apparel” as a whole industry is one of the most environmentally impactful, second maybe to transportation. This is due to a few factors:

- It requires a lot of time, energy and resources to create a garment. There is a huge “cost” associated with just getting it to the point where you can buy it. Nevermind the price tag. This is irrelevant to what you pay for that garment. In other words, from an environmental perspective “cheap” clothing is nothing but “cheap”.

- There is a disposable culture around apparel - consumers buy garments to wear them only a few times, then discard them - even if they are well made. Then there are garments “designed” for that disposable culture - made very cheaply in large volumes to meet a price point, at any cost.

- The general system or supply chain is not designed to be sustainable. It was designed based on the above points: low cost, high volume. This results in high carbon impact and huge amounts of excess.

Given that we’re a microscopic company in this vast industry, we don’t have the ability or the resources to fundamentally change the process. Instead, we’re looking at ways that we can optimize what and how we produce within the supply chain and manufacturing process. This includes:

- Using the highest quality manufacturing partners - both at the materials level as well as the garment manufacturing level. This becomes significant, since our suppliers are aligned philosophically in how they operate - looking at ways to improve efficiency and energy consumption through renewable energy such as solar, providing a safe work environment and and fair wages for workers and adhering to the highest standards for environmental and social impact.

- Sourcing materials, such as recycled and biodegradeable fabrics that are reclaiming what we can from used material, or ensuring that at the end of the garment’s lifecycle, that it doesn’t live on forever in a landfill. And looking deeper into *how* those fabrics are sourced. For example, understanding how recycled yarns are sourced can mean the difference between creating a fabric that has a higher carbon footprint due to where it’s produced. The materials we use cost us more, but we’re committed to investing in these types of materials because we feel it’s the best possible option today.

- Transportation and packaging are pretty huge too. This comes at every stage: sourcing yarns and fabrics to delivering finished goods to our distribution centers and on to the end customer. There are many areas here that we’re looking at how we can minimize impact while still providing the highest quality service. Using ocean freight and truck service whenever possible, versus air shipments, has a profound impact on carbon footprint. And on our packaging side, we’ve looked at how we can reduce the amount of packaging we use and what it’s made out of - it’s the biggest driver in packages arriving to our customers in biodegradeable bags and compostable mailers. We don’t do fancy elaborate packaging because we are willing to forego the unboxing experience to reduce the amount of waste. We’d rather the experience with our apparel be outside exploring the world around us.

But, if I had a magic wand and were able to make sweeping changes, I would do two things:

- I’d rebuild the apparel (and many other) industries to be circular and focused on sustainable practices, high quality products that last, and ways of recycling and repurposing what we do use. We need apparel, but we don’t need to produce apparel the way that we do.

- I’d develop a manufacturing “cost” label system that goes on every product you buy. Much like a nutritional or energystar label, it would be designed to inform the customer of the true cost (meaning the resources required) to produce that product. It would include several categories, such as materials, transportation, ethics/social responsibility and energy consumption and all of that would be reflected in a score. This would allow consumers a more transparent look at what they are buying - not just the cost to them when they make their purchase.

What is something you’re doing with design or manufacturing that might not be readily apparent to a rider? Can you speak to proprietary fabrics and patterns a bit?

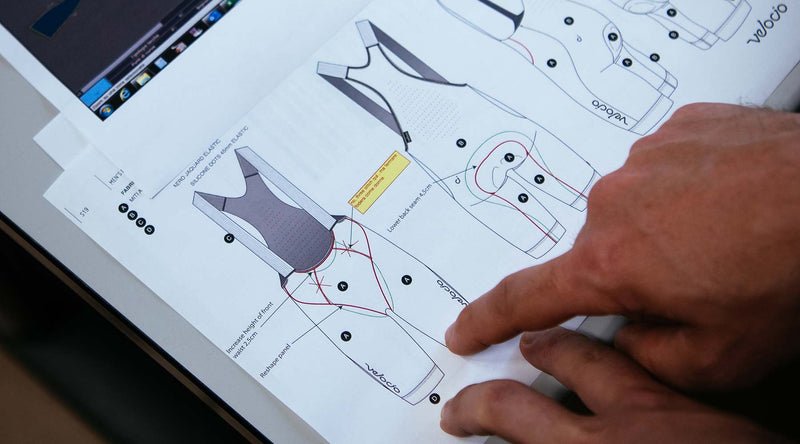

Everything we create is in many ways proprietary. This is true out of the fact that we don’t start with someone else's patterns or fabrics. We really do develop everything we produce from a blank sheet.

We also work with our suppliers to see how we can push to develop new materials or constructions that are all elements in addressing that rider-first problem we are trying to solve with that garment. Most recently, our eVent softshell fabric or our Concept bib short and pad are good examples of how we not only design what we want something to look like, we work at every level in a collaborative way with our partners to realize products that are truly unique.

This goes back to the very beginning of Velocio when we developed the Fly design, then redesigned it (and made it obsolete) with FlyFree. In a way, our design approach is how we have approached building Velocio - by taking a step back from what’s considered the norm and looking for another path forward. That path is often more challenging, but the end result is something far better and more imaginative than walking the line.